BioDEN

BioDEN: Biorefinery approach to exploit digestate as key feedstock in the energy - nutrient nexus

Turkish version: https://www.ostimenerjik.com/bioden-projesi-1211

English version: see below

De afzet van digestaat blijft een uitdaging in Vlaanderen die het business model van de biogasinstallaties onder druk zet. Met het onderzoeksproject BioDEN wil Biogas-E, samen met Vlaamse en Turkse partners, de rendabiliteit van vergistingsinstallaties verhogen door het realiseren van een doorgedreven valorisatie van het digestaat.

Het innovatiedoel van dit project is de waarde van digestaat te verhogen, door enerzijds een verwerkingscascade te implementeren om nutriënten (N, P, K, C) terug te winnen en anderzijds energiedragers (biogas) te produceren gekoppeld aan de anaerobe vergisting. De gegenereerde producten zullen grondig worden doorgelicht op basis van kwaliteit en het potentieel te beantwoorden aan de RENURE-criteria.

Met steun van:

|

|

Het project werd ingediend via de CORNET oproep, met Vlaamse partners Universiteit Gent, KU Leuven, VCM en Biogas-E, in samenwerking met Turkse partners Ostim Enerjik en Marmara Universiteit. Het project duurt twee jaar (en vier maanden door verlenging) en start begin januari 2022.

English version:

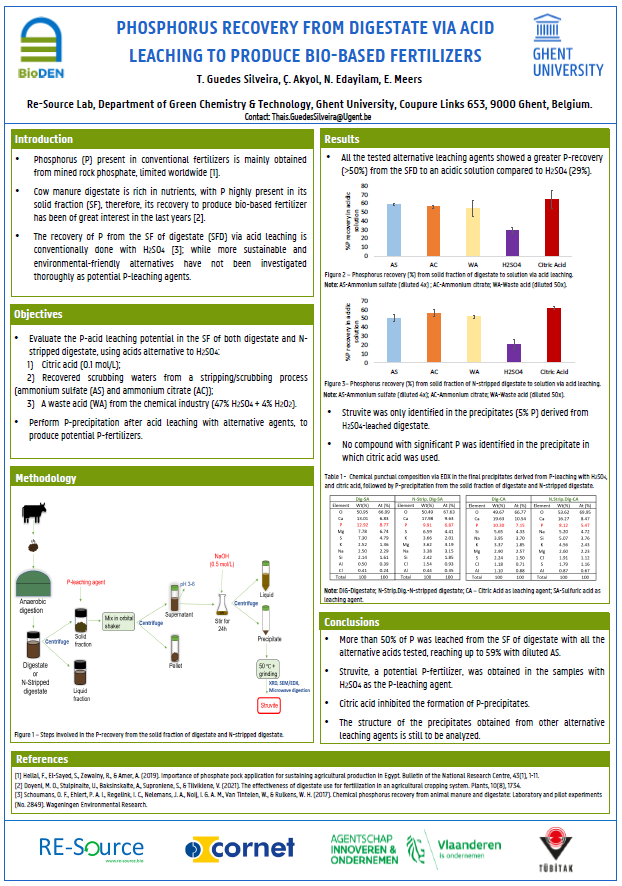

The application of digestate as fertilizer remains a challenge in Flanders and Turkey. This challenge is a burden for the business model of biogas plants in both countries. The BioDEN project aims to create extra revenues for the biogas sector via developing a technology cascade approach for an integrated enhanced biogas production and efficient recovery of nutrients (N, P, K) as (novel) bio-fertilisers from digestate.

The target of the project is to increase the value of digestate by focussing on different elements: (i) enhanced biogas production via anaerobic digestion (AD), (ii) ammonia recovery via stripping and scrubbing, (iii) phosphorus recovery via precipitation and adsorption and (iv) integrated value chain assessment, including pot trials and scenario analyses. Although some of the processes already receive attention in research and in industry, effective linking of the processes to obtain a successful cascade is still missing.

Concretely, the BioDEN-project will result in (i) 10-20% more biogas (at constant input) compared to standard current practice, due to reduced ammonia inhibition, release of bio-available organic matter and high organic loading rates, (ii) an increase in CH4 content of the biogas by 3-5% due to CO2-stripping, (iii) optimised processes for the recovery of nutrients into novel (ammonium citrate, ammonium bicarbonate) and known (ammonium sulphate, struvite, calcium phosphate) bio-fertilisers.

The BioDEN consortium is composed of 6 partners carefully selected by the project coordinator, Biogas-E (BE). It involves a balanced expertise composition of 3 RTOs and 3 Association Organisations (AO) from Flanders (BE) and Turkey. Innovation and research activities will be carried out by KU Leuven (BE), UGent (BE) and UMARMARA (TR) Universities, each specialised in different aspects of the full BioDEN concept. AO VCM (BE) will provide essential expertise for the technical, economic and ecological impact assessments of the final technologies and products.

With support of:

|

|

BioDEN is lid van de / BioDEN is member of Biorefine Cluster Europe

Focus

English version: see below

Het project is opgebouwd uit vier focusthema’s:

1. Recuperatie van stikstof onder de vorm van ammoniak en ammoniumzouten

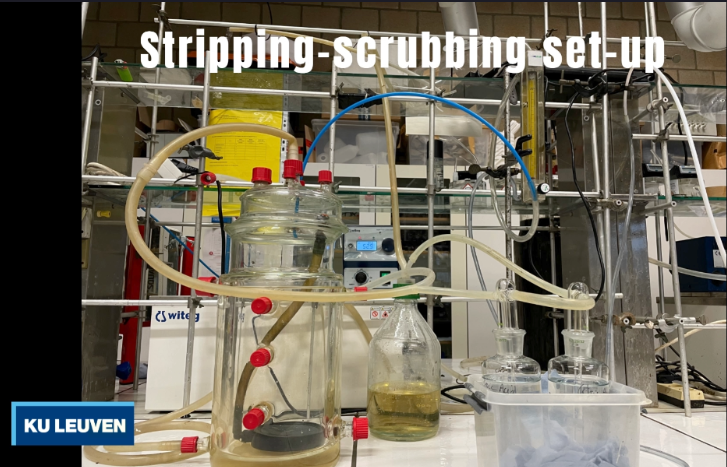

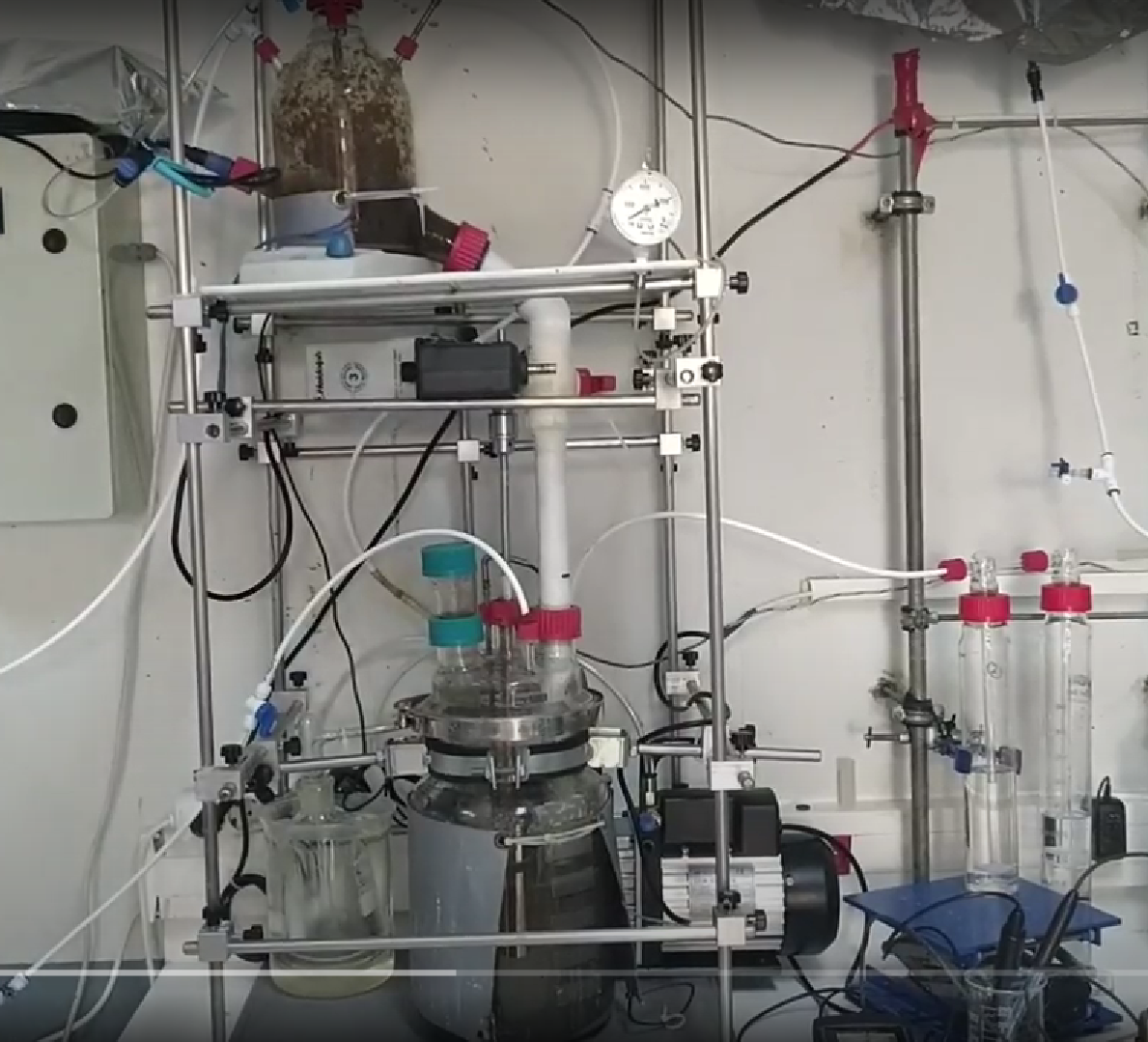

Enerzijds wordt de recuperatie van ammoniak via vacuümstripping van het digestaat onderzocht. Het N-arme digestaat wordt daarna gerecirculeerd om de positieve effecten op de verdere afbraak van de koolstoffractie te onderzoeken. Anderzijds wordt het gebruik van alternatieve, duurzame zuren zoals organisch citroenzuur en CO2 onderzocht op hun potentieel om ammoniak uit de gasfase te wassen via stripping-scrubbing.

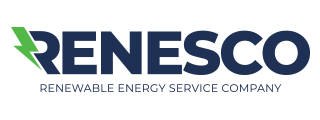

2. Terugwinning van fosfor uit vloeibare en vaste digestaatfracties

Twee verschillende technologieën voor de herwinning van fosfor uit digestaat worden toegepast op de vloeibare en vaste fracties van het digestaat. Voor het oplosbare fosfor in de vloeibare fractie worden Mg- (struviet) en Fe-gebaseerde precipitatietechnieken getest. P-precipitatie uit het digestaat in de vaste fase wordt onderzocht met behulp van zuuruitloging op drie manieren: klassieke zuuruitloging, biologische aanzuring en zuuruitloging met het N-scrubberwater (spuiwater).

3. Maximalisatie van het energetisch potentieel van het vergistingsproces

De energetische inhoud van (behandeld) digestaat wordt verkend via de recirculatie van het behandeld digestaat naar de vergister of via opstellingen met een navergistingsstap. Parallel worden methaanverrijkingstechnieken voor het digestaat geanalyseerd.

4. Waardeketen en productbeoordeling

In het laatste thema worden de gerecupereerde digestaatproducten en de hele waardeketen geëvalueerd. De waardeketenbeoordeling wordt uitgevoerd op drie niveaus: implementatie van trapsgewijze strategieën, CO2-emissiereductiepotentieel en economische evaluatie. De productbeoordeling houdt een evaluatie in van de digestaatproducten naar samenstelling en kwaliteit, inclusief potproeven, enerzijds en hun potentieel als RENURE-meststof anderzijds.

Het project werd ingediend via de CORNET oproep, met Vlaamse partners Universiteit Gent, KU Leuven, VCM en Biogas-E, in samenwerking met Turkse partners Ostim Enerjik en Marmara Universiteit. Het project duurt twee jaar (en vier maanden door verlenging) en startte begin januari 2022.

BioDEN is lid van de Biorefine Cluster Europe

English version:

The project is composed of four focus themes:

1. Recovery of nitrogen in the form of ammonia and ammonium salts

On the one hand, the recovery of ammonia via vacuum stripping of the digestate is investigated. The N-poor digestate is then recirculated to investigate the positive effects on further decomposition of the carbon fraction. On the other hand, the use of alternative, sustainable acids such as organic citric acid and CO2 are investigated for their potential to wash ammonia from the gas phase via stripping-scrubbing.

2. Recovery of phosphorus from liquid and solid digestate fractions

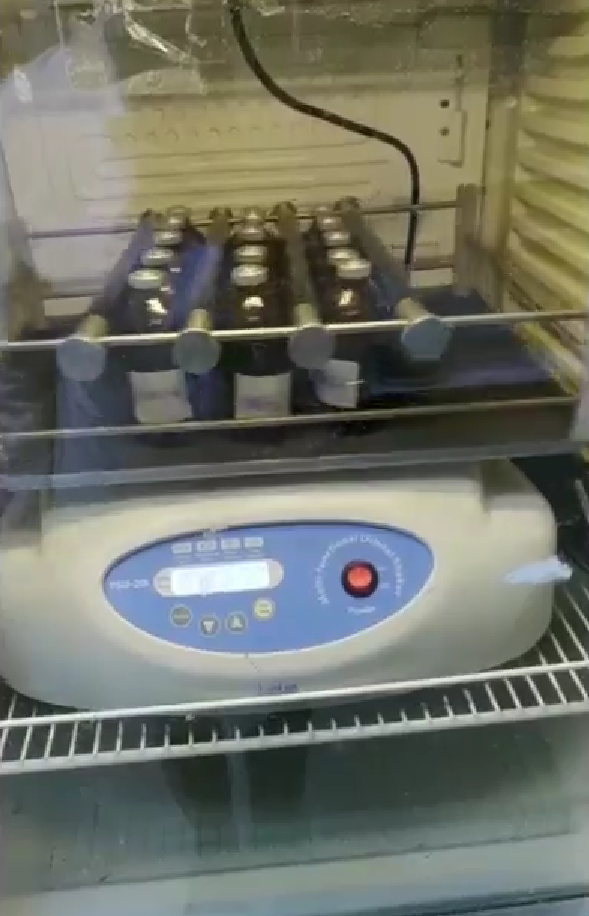

Two different technologies for phosphorus recovery from digestate are applied to the liquid and solid fractions of the digestate. For the soluble phosphorus in the liquid fraction, Mg (struvite) and Fe-based precipitation techniques are tested. P-precipitation from the digestate in the solid phase is investigated using acid leaching in three ways: classical acid leaching, biological acidification and acid leaching with the N-scrubber water (scrubbing water).

3. Maximising the energetic potential of the digestion process

The energetic content of (treated) digestate is explored via recirculation of the treated digestate to the digester or via set-ups with a post-digestion step. In parallel, methane enrichment techniques for the digestate are analysed.

4. Value chain and product assessment

The last theme evaluates the recovered digestate products and the entire value chain. The value chain assessment is carried out at three levels: implementation of tiered strategies, CO2 emission reduction potential and economic evaluation. The product assessment involves evaluation of digestate products by composition and quality, including pot tests, on the one hand, and their potential as RENURE fertiliser on the other.

The project was submitted through the CORNET call, with Flemish partners Ghent University, KU Leuven, VCM and Biogas-E, in collaboration with Turkish partners Ostim Enerjik and Marmara University. The project will last two years (and four months by extension) and started early January 2022.

BioDEN is member of Biorefine Cluster Europe

Met steun van/with support from:

|

|

| Project Partners | contact | |

|

Biogas-E: project coordinator |

Tine Vergote tine.vergote@biogas-e.be |

|

Katholieke Universiteit Leuven | Lise Appels |

|

Ghent University | Erik Meers |

|

Marmara University | Baris Calli |

|

VCM | Astrid D'Haene |

|

OSTIM ENERGJIK | Pinar Akcengiz |

| Members of User Commitee | |

|

|

Vlaco npo was founded in 1992, to support and implement the policy of biowaste in Flanders. We are a membership organisation with representation of the Flemish government and the private sector including AD installations – both agricultural, industrial or intermunicipal.. All techniques are best available techniques (BAT) and monitored as such through Vlaco’s quality control. All of Vlaco’s activities are intended to defend the interests of the sector and support the sustainable material cycle of biowaste. Vlaco pursues, within the framework of green energy, a synergy of material and energy recuperation. Vlaco is affilitated to EBA (European Biogas Association), ECN (European Compost Network) and supports an European QAS (Quality Assurance Scheme). Vlaco has wide knowledge to disseminate as to the availability, use, and benefits (agronomic, economic, and ecologic benefits). Vlaco has (co-)conducted or been part of several research-projects in recent years (Interreg Biorefine, H2020 Nutriman, VIS DIMA, NpirriK, UNIR, Tetra Recidigest,..). |

|

|

Istac Inc. is a premier waste management company in Turkey. By the time Istac Inc. was established as a municipal corporation in 1994 in Istanbul, the company had become the first landfill operator and quickly became one of the Turkey's largest recycling, services and disposal companies. By focusing on high-quality public services, integrated waste management practices and environmental research and development, Istac Inc. has maintained a unique reputation for environmental management. Vision Statement; our vision is to obtain a more livable environment by producing sustainable solutions and creating environmental awareness in compliance with international standards. Contact Person : Mehmet GENCOSMANOĞULLARI – R&D Supervisor |

|

|

ARTAŞ, established in 1982, is the pioneering, engineering, manufacturing and contracting company specialized in Environmental Protection Technologies and Renewable Energy. ARTAŞ’ s expertise is capitalized on 40 years of engineering and manufacturing legacy of ARTAŞ sister companies in Finland, Germany and Turkey. We design, produce and implement: Water, Waste, Air and Bioenergy solutions. Our technologies solve problems dealing with;

We designed and supplied over 450 customers globally. Our philosophy is providing integrated, customized, tailor made, stand-alone solutions. As a one shop solution provider, we design, manufacture, implement and operate fully integrated solutions without any third party intervention. ARTAS has dozen of patents and utility model certifications along with CE marking, ISO 9001, ISO 14001 and ISO 45001 Certificates. ARTAŞ ENDÜSTRİYEL TESİSLER TAAHHÜT VE TİCARET A.Ş. Address: Cihannuma Mah. Bostancibasi Sok. No:8A 34353 Besiktas/Istanbul/Turkey |

|

|

Inagro is a research and advisory center for agri- and horticulture in Flanders (Belgium), with a long-standing experience (since 1965) in applied research and advice to farmers. It has several departments working in almost all aspects of agriculture (animal husbandry, open air horticulture, arable farming, greenhouse vegetables, edible mushrooms, organic farming, …). The department of Energy and Circular Economy has a lot of experience with research projects on nutrient recovery and anaerobic digestion (e.g. Nutri2Cycle, Nutriman, Nitroman, ReNu2Farm, Pocket Power, Pocketboer, Biogas-MAMBO, …). For this purpose, Inagro has its own plug &play farm scale anaerobic digester (31 kWel) for research and demonstration purposes. Next to this, Inagro coordinates a living lab on circular economy. Furthermore, Inagro has an accredited lab for soil, water, manure and crops analysis. Specialist laboratory equipment are ICP-MS & ICP-AES, segmented flow analysis, automatic titration, ion chromatography, high pressure liquid chromatography, Q-PCR & conventional PCR, Kjeldahl analysis, Capillar electrophoresis, … website: www.inagro.be |

|

website: www.biolectric.be |

|

website: www.biotecharge.com.tr |

|

website: www.circularvalues.eu |

|

website: www.colsen.nl |

| website: www.detricon.nl | |

|

website: guilliamsgroup.be/green-power |

| website: www.innolab.be | |

|

website: www.renesco.com.tr |

|

website: www.seleda.com.tr |

|

website: www.solvakem.com/nl |

|

website: www.ulucev.com.tr |

|

website: www.dewaterhoek.be (Van Dessel automatisatie) |

|

website: www.waterleau.com |

|

website: www.zeta-water.be |

Projectverwezenlijkingen

Nieuwsbrieven

- BioDEN: Wat hebben we bereikt in 2022?

- BioDEN: Richting een gesloten nutriëntenkringloop

- BioDEN: P-terugwinning via zure uitloging

- BioDEN: P-terugwinning vanuit vloeibare fractie van digestaat

- De successen van het BioDEN project

- BioDEN: Prestaties technologiecascades, bio-meststoffen en bodemverbeteraars

Factsheets

WP 1 Verhogen bio-energie opbrengsten via alternatieve vergister operatie

WP 2 Ammoniak terugwinning van digestaat

WP 3 Fosfor terugwinning van vloeibare en vaste fractie digestaat

Digitale brochure

Project in de kijker

|

|

|

|

|

|

|

|

|

|

|

|

|

|